ROPS / FOPS Safety

Roll Formed ROPs and FOPs Tube Safety Components

Structural Tube Fabrication Expertise & Solutions

When you partner with Roll Forming Corporation, you’re partnering with a company that takes personal safety as seriously as you do. Roll Forming Corporation is a globally respected off highway, ROPS and FOPS cabs and custom roll formed tubing supplier. We are known for our innovative, high-quality components and metric tubes.

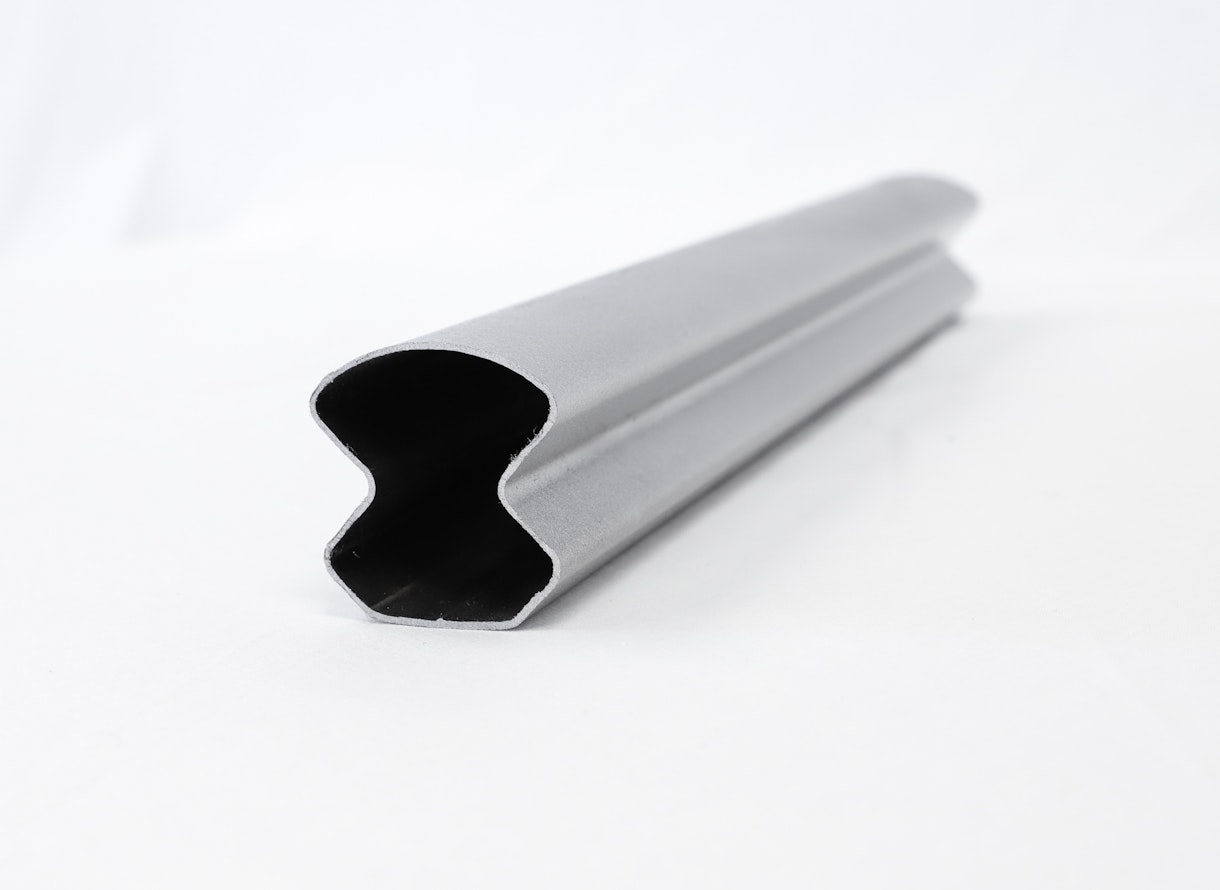

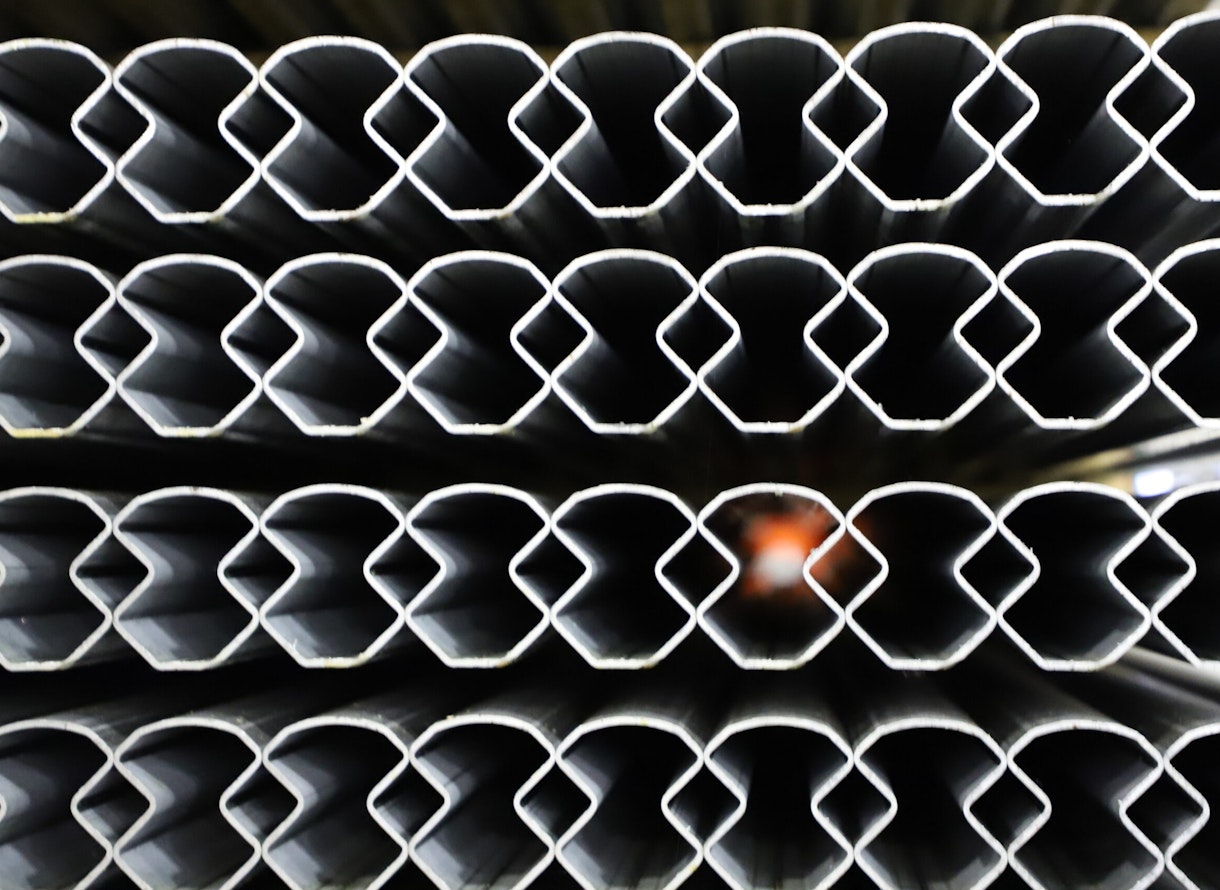

We ensure that our ROPS and FOPS high-frequency welded tubes meet or exceed the highest strength and durability standards in the world today. We offer the highest level of protection by utilizing 100% in-line, non-destructive weld validation testing (NDT), die penetrate testing, and weld destructive testing. You can choose from one of our standard tube designs, or we can customize a tube to meet your specific requirements.

Engineering Expertise for Roll-Over Protection and Falling Object Protective Safety Structures

At Roll Forming Corporation, we have the engineering and technological expertise to customize components, to your specific design. This value-adding capability allows you to explore and test design options before manufacturing, bringing your ideas to life efficiently and cost-effectively. RFC offers customized solutions for ROPs and FOPs metric tubing, utilizing technologies such as tube laser cutting, tube bending including roll, draw and sweep producing high-quality components to ensure high-frequency welded sections meet or exceed the highest strength and durability standards.

Standard and Customized Structural Tube Fabrication SolutionsTubes, Bent Tubes and Tube Fabrication

We offer custom and standard tube design. Our in-house expertise and technologies specialize in processing various steel grades, including ultra and advanced high strength. All of this plus tube fabrication all under one roof.

What are the advantages of custom ROPs structural tubing?

Key advantages of custom ROPs compared to standard shapes.

Local and Global Reach in Metal Forming

Based in Indiana, Roll Forming Corporation is a roll forming supplier serving North American customers quickly and efficiently. Locally we offer tube bending, tube laser cutting, tube mill and custom roll forming all under one roof. If a global solution needs to be found, we can work with our world-wide affiliate metal forming companies to make it happen. Our affiliation with the voestalpine Group means that we can collaborate with some of the world’s best manufacturing minds. voestalpine’s vast R&D capabilities and availability of capital allow us to create and develop innovative new products and bring those products to market. and As a components fops rops manufacturer, our fops and rops tubing ensures quality rollover and fall over protection systems for your end market product.